Screening and Fiber recovery

Continuous improvement strategies for screening

The art of screening improvements

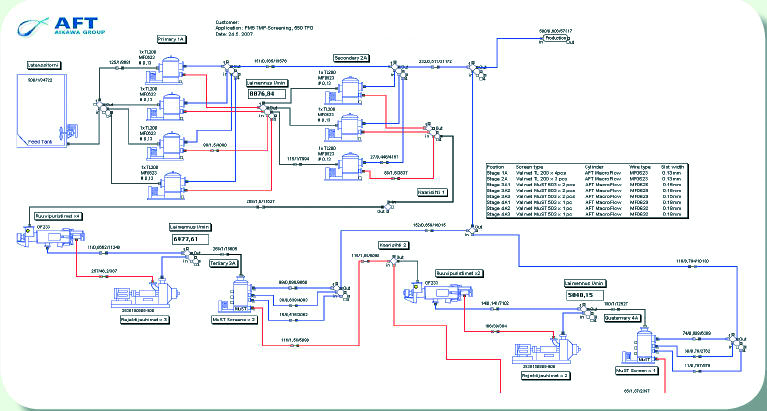

Improvements to an existing screening system can come from upgrading performance wear components, replacing or upgrading equipment, or a unit capital addition. For a recycling line this means a step-wise evaluation of the entire screening system: coarse, fine, headbox screens and reject fiber recovery. We begin with a solid baseline of the existing process and a list of challenges or future visions desired. Our experienced engineers then simulate the process with possible changes using our SimAudit™ software to determine where the best returns may be.

Real solutions

Continuous screening improvement may include:

- Upgrades to screen cylinders: Improve efficiency, extend life

- Upgrades to rotor: Save energy, reduce wear rates

- Replace or upgrade old equipment: More capacity, less energy

- Focused unit capital addition: Improve efficiency, fiber recovery, capacity

Working in stages, being budget flexible or doing it all at once - we can help you determine the best plan, including investment returns.

Performance from the Inside

Performance Components

The most critical elements for optimum screening efficiency, energy use and capacity are the screen cylinder and the rotor. So looking at these key performance wear components is a logical place to start any improvement strategy. We develop a process flowsheet to determine how reject and accept streams are being handled, whether the process capacity aligns with these elements, and where are potential improvement areas that can be quantified.

We are constantly advancing technology - so what was best before may no longer be. Our advances in screen energy efficiency have been significant - with most investments returned within the first year!

Start with a current process baseline

Sometimes new equipment just makes sense - as long as there is an investment return. AFT has a variety of screening equipment options, along with extensive experience in unit capital upgrades to help with basic engineering and equipment selection, including:

- Coarse and fine screens: MaxFlow™- with custom internals or ADS™

- Headbox screens: MaxFlow™ outflow or Aikawa-B inflow

- Reject tail screens: MaxSaver™ or CoarseSorters (vertical-CRS and horizontal-Alpha)

- Detrashing: MaxiTrasher continuous system to recover fiber from pulper rejects

Opportunities with value