Fiber Deflaking

MaxFlaker Series – Deflakers for all furnishes

Recycled fiber deflaking

Generally the task of fiber separation or deflaking in a shorter fiber furnish is less challenging, except when wet strength additives are involved. For these furnishes the SevenFiner series is offered. This machine is best designed to handle wet strength in waste papers such as heavy broke, OCC, and MOW furnishes.

The SevenFiner deflaker is a multi-stage high-speed machine that combines a conical hydrodynamic separation zone and a disc plate for secondary deflocculating of small fiber bundles. This unit allows some important flexibility for shifts in stock composition: whether a change in broke or a different mix of waste paper, the disc plate gap can be adjusted to add or remove secondary deflocculation intensity.

SevenFiner™ Unit

TopFiner™ unit

Hardwood deflaking

The TopFiner deflaker is used to prepare hardwood market pulp for paper making. This deflaker uses a unique high-speed rotation and surface design to separate very fine, tight fiber bundles that are typical in hardwood pulps. An intense hydrodynamic action is created by a rotating ring-shaped deflaking surface and a stationary opposing surface - however, the action does not refine individual fibers so as to minimize freeness reduction. This compact model uses less floor space than most deflakers on the market.

Softwood and high capacity deflaking

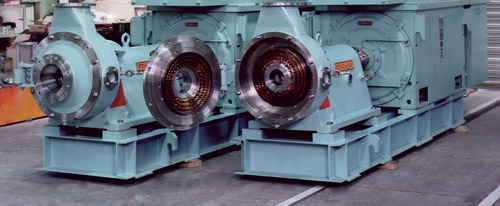

The ADF Double Flaker is a similar design to the TopFiner deflaker except that it boasts a twin flow system - like having two deflakers in one. This design is especially suited to long softwood fibers and very high capacity deflaking of recycled or market pulp furnishes, without significant freeness loss.

ADF Unit